Process

WOOD BLOCK CARVING:

“Everything beautiful first takes shape in mind”

The prints that we create for you are first visualized by our designers who sketch the drawings on a white paper. These sketches are then taken up by experienced artisans who meticulously carve out intricate blocks.

PREPARING THE DYES :

MAKING MAGIC HAPPEN

Colors bring life to our prints. Choosing the right complementary hues from natural sources is where we put a lot of our energies. This process of Dyeing / Color Mixing is no less than a magic trick, where colors play with each other and create more of themselves.

A combination of naturally found elements are used to create a few different basic colors, which can then be mixed together to make several varied colors. For example, Pomegranate is boiled with water to create a mustard yellow color. Red is created by mixing natural gum paste and alum.

WASHING :

PREPARING THE PERFECT FABRIC

We purchase the finest Organic cotton fabric from the market. The artisans beat the wet lengths of cotton on river stones worn down by years of use to make them softer, and then lay them out to dry and be naturally bleached by the sun. This process gets rid of any dust particles & traces of dirt, and takes us one step closer.

HARDA DYEING :

GETTING READY FOR PRINT

For the fabric to absorb dyes properly in the next steps and for the colors to come out as aesthetically pleasing as we want, the cloth is first treated with Harda.

The fabric is dyed in cool water and harda powder. Harda has tannic acid in it and acts as a primer. Once dyed, the fabric needs to lay flat and dry in the sunlight. The fabric will have a yellowish tint after this step which will later disappear once washed.

WASHING & BOILING :

FINAL MEASURES DONE RIGHT

Senior Vice President

Every step in the process is equally crucial, and so is Washing & Boling. After the printing process is completed, the fabric is washed in cool water.

After cooling, comes boiling where color fastening takes place with the help of flowers from Dhaura tree. Pieces with red dye is boiled in a separate pot with alizarin which then turns the once yellowish color red.

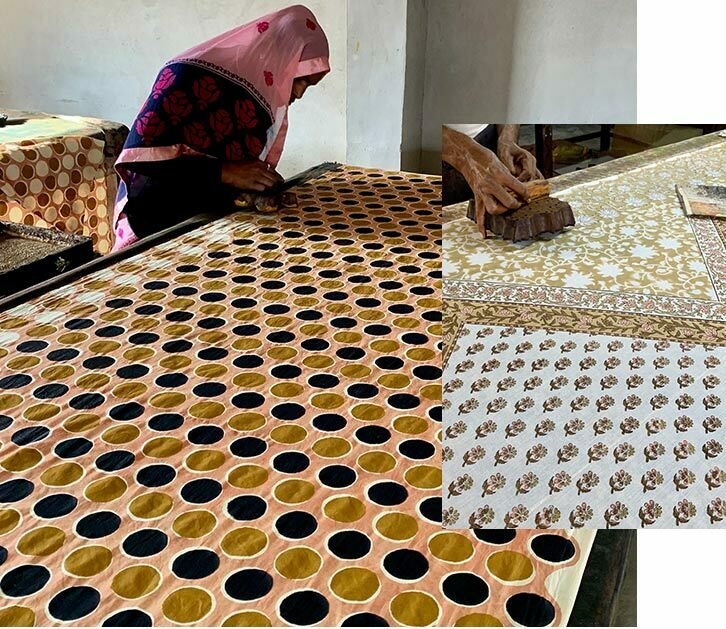

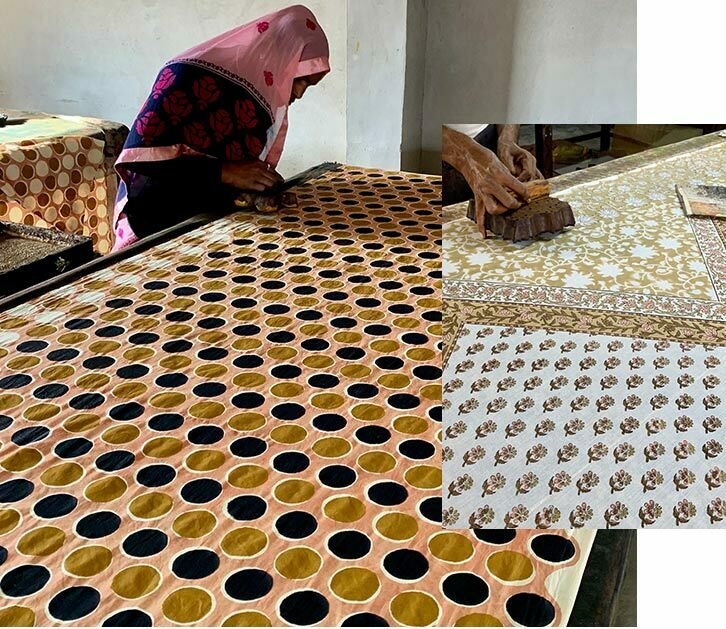

BLOCK PRINTING :

AN ARTISTIC ENDEAVOUR

This is where the imperfections makes everything just better. The process of block printing demands precision as the pattern must be stamped repeatedly across the fabric, color by color. Each color pattern is stamped individually on to the fabric.

The slight human irregularities makes it possible for every fabric to be unique and creating an artistic effect which wouldn’t be possible otherwise.

DRYING :

GETTING THE BLEACH ON!

Senior Vice President

It’s time to see everything coming together and appreciate this technique. Once boiled, the cloth is given a quick rinse, a quick spin to dry and that’s it! Now it dries in the sun and we bet you can’t wait to order one of those.